HPMC - HIGH SPEED HDPE PIPE PLANT

HPMC HDPE pipe plant is state-of-the-art extrusion machinery as to produce an extensive range of HDPE pipes and other utility products from HDPE (High-density polyethylene) to be used and employed in a variety of product utilities in various industries for innumerable purposes. Our High-Speed HDPE Pipe plant available in model numbers HPMC 45G, HPMC 65G, HHPMC 75G and HPMC 90G made from high-grade steel produces very effective pipes in min PIPE OD (mm) and max PIPE OD (mm). The plasticized capacity of the HPMC-High Speed HDPE Pipe Plant ranges between 550 kg/hr to 600 kg/hr.

Product Description:

Our range of High Speed HDPE Pipe Plant range available in model numbers such as HPMC 45G, HPMC 65G, HPMC 75G, and HPMC 90G is very effective in producing array and range of HDPE products in varying utilities and according to usages across industry sectors and segments.

Salient Features of High-Speed HDPE Pipe Plant

- It is designed for easy operability and performance optimization.

- Screw & Barrel, PLC control system and Spiral Type Die Head and other parts of the High Speed HDPE pipe plant are designed in manner to bring optimum result and ensure better productivity results.

- Made to ensure durability and longer life

- Energy efficient ensuring lower power consumption

- Corrosion resistance

SECTIONS OF THE HIGH-SPEED HDPE PIPE PLANT:

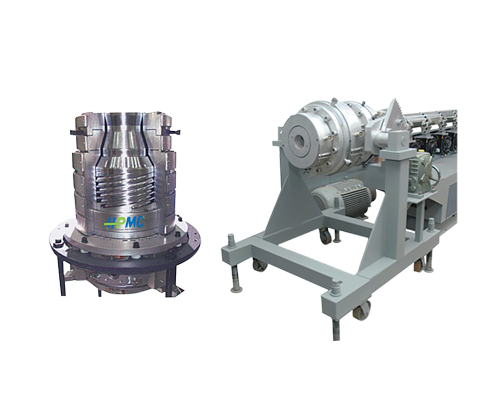

1. SPIRAL TYPE DIE HEAD

- Spiral type die head ensures stable wall thickness of PE pipe even at higher output.

- It can produce pipe upto630mm

- Low-pressure diagonal channel with spiral mixing part ensures extrusion at low temperature and homogeneous plasticization.

2. SCREW AND BARREL

- The screw adopts a barrier-type mixing zone.

- The barrel feeding zone is a groove feed bush and made of hard alloy.

- It is result in higher output rates, homogeneous plasticizing, and material slippage

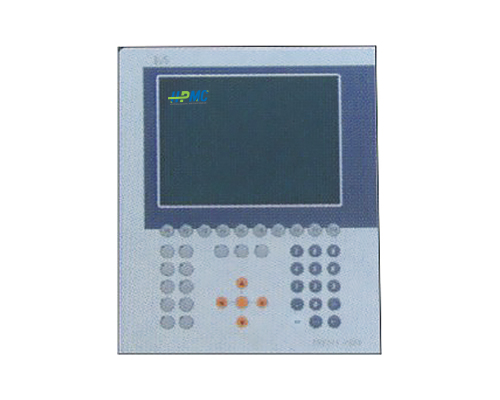

3. PLC CONTROL SYSTEM

- There is an option for the whole line with a PLC control system and large liquid crystal screen which makes the operation very convenient..

4. VACUUM TANK

- Special design vacuum sizing can ensure the stability of diameter and roundness even when producing the pipe with higher wall thickness.

- The water spray unit produces a high-speed spray vortex to achieve a fine and even cooling effect.

- Optimum performance

- Durable

- Corrosion resistance

- Low power consumption

- Easy operation

- The screw adopt barrier type mixing zone.

- The barrel feeding zone is groove feed bush and made of hard alloy.

- It is result higher output rates,homogeneous plasticizing and material slippage

- Double station coiler can be provided for diameter up to 63mm.

- Single station coiler can be provided for diameter up to 110mm.

5. MULTIPLE ARM HAUL OFF

We provide multiple arm haul off which is used for PVC pipes. It has multiple arms maximum up to six for diameter of 630 mm. The multiple arm haul off provides perfect roundness of higher diameter pipes. Developed using high grade steel, our gamut meets the requirements of clients.

Features:

6. PLANETARY CUTTING SAW

7. DOUBLE/SINGLE STATION COILER

Technical Specifications:

| MACHINE MODELS | HPMC 45G | HPMC 60G | HPMC 75G | HPMC 90G |

| Min Pipe OD ( mm) | 20 | 20 | 63 | 315 |

| Max Pipe OD (mm) | 110 | 200 | 250 | 630 |

| Max Plasticizing Capacity (Kg/hr) | 150 | 200 | 350 - 400 | 550 - 600 |

| Max Output (Kg/hr) | 140 | 180 - 200 | 350 | 550 |

| Main Drive (Kw) | 37 | 55 | 110 | 175 |

| Heating | ||||

| Barrel ( Kw) | 8 | 12 | 20 | 28 |

| Die ( Kw) | 4 | 5 | 15 | 22 |

| Screw Speed Variation (RPM) | 30 - 120 | 30 - 120 | 30 - 120 | 30 - 120 |

| Vaccum Sizing Tank | ||||

| Pump Drive ( KW) | 2.25 | 2.25 | 2.25*2 | 7.5*2 |

| Length ( Mtrs) | 6.0 | 6.0 | 6.0 | 6.0 + 6.0 |

| Water Requirement Circulating ( Ltrs/mm) | 450 | 450 | 600 | 1200 |

| Spray Bath | ||||

| Length ( mtrs) | 6 | 6.0 | 6.0*2 | 6.0*3 |

| Water Circulating Requirement ( Ltrs/mm) | 450 | 450 | 1000 | 1500 |

| Haul Off | ||||

| Drive Range (KW) | 3.7 | 3.7 | 5.5 | 7.5 |

| No. of Arms Option 1 | 2 | 2 | 3 | - |

| No. of Arms Option 2 | - | - | 4 | 6 |

| Cutting Saw | ||||

| Saw Diameter ( mm) | 400 | 500 | 200 | 200 |

| Saw Drive Load ( KW) | 0.75 | 1.5 | 3 | 5.5 |