HPMC - PVC PIPE PLANT - CONICAL TWIN SCREW EXTRUDER (Single Pipe)

HPMC Conical Twin Screw Extruder for two die is made of high-grade steel. Efficient for low power consumption and more quantity of small and big pipes (125 kg/hr, 150 kg/hr) and available in Conical Twin Screw Extruder Models, HPMC 45/90, HPMC/51/105, HPMC 65/132, HPMC 80/156, HPMC 92/188.

Product Description:

HPMC Conical twin screw extruder in the range of PVC pipe plant is available in models HPMC 45/90, HPMC/51/105, HPMC 65/132, HPMC 80/156 and HPMC 92/188. The conical twin screw extruder provides with compact and reliable gear box and equipped with bi-metallic screw & barrel for longer life and are the most suitable for manufacturing various types of PVC

Salient Features of Twin Screw Extruder:

- Twin Screw Extruders come in an extensive range of extruders with screw diameters varying from 20mm to 150mm.

- HPMC PVC Pipe Plant-Twin Screw Extruder is a Barrier design (Double thread) Screw for PVC Pipe and it performs consistent melt homogeneity, excellent and efficient process control, and stability for unmatched end-product quality and delivery.

- It is designed to work according to all pelletized materials.

- The output rate for polyolefin’s up to 450 Kg/hr.

1. Die Head

- Die Head is made of high carbon content forged alloy steel for better life and performance.

2. Spray Bath

- Intensive cooling of the pipe with the help of number of spray nozzles.

- Axial adjustment of tank on slide rails with locking arrangement.

- Self cleaning type spray nozzles with wide openings for intensive cooling of the pipe.

- Acrylic transparent cover for easy inspection has been involved and included in conical twin screw extruder for single pipe.

3. Caterpuller Pneuamtic Haul Off

- Twin and Multi Track system

- Track can be adjusted for different sizes of pipes 20mm to 315 mm

- Haul-off is synchronized with extruder with the help of AC Frequency Variable Drive.

- Gap between two tracks and pressure is adjusted pneumatically in the conical twin screw extruder for single pipe.

- V-Groove rubber pads mounted on chain with proper tensioning to prevent becoming oval in shape even for large diameter and thin wall pipe.

4. Planetary Cutting Saw

- Planetary saw blade cutting for pipe dia upto 315 mm

- UPVC chamefering rotary cutting.

- Cutting is PLC controlled.

- Saw dust powder sucking device.

- Special hard alloy saw blade employed to cut heavy caliber thick wall pipes.

5. Automatic Cutting

- Carborundum cutter for less wastage during cutting.

- Smoot and clean cut are ensured with the conical twin screw extruder

- All movement are equipped with pneumatic cylinders.

- Clamping force can be adjusted to accomodate different wall thickness.

- Limit switch is provided to sense particular length.

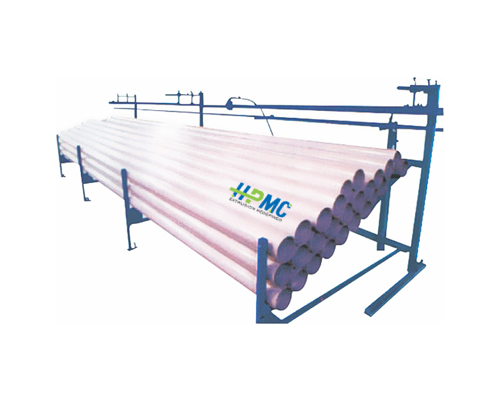

6. Tipping Chute

- Operated with pneumatic cylinder and limit switch for pipe stacking for the best conical twin screw extruder working results for single pipe production .

Technical Specifications

| MACHINE MODELS | HPMC 45/90 | HPMC 51/105 | HPMC 55/110 | HPMC 65/132 | HPMC 80/156 |

| Min Pipe OD ( mm) | 16 | 16 | 16 | 63 | 110 |

| Max Pipe OD (mm) | 50 | 200 | 200 | 225 | 315 |

| Max Plasticizing Capacity (Kg/hr) | 90 | 170 | 190 | 300 | 425 |

| Max Output (Kg/hr) | 80 | 150 | 170 | 250 | 350 |

| Main Drive (Kw) | 15 | 18.5 | 22 | 37 | 55 |

| Heating | |||||

| Barrel ( Kw) | 11 | 15 | 18 | 20 | 35 |

| Die ( Kw) | 3 | 5 | 5 | 8 | 12 |

| Screw Speed Variation (RPM) | 1 - 37 | 1 - 37 | 1 - 37 | 1 - 37 | 1 - 37 |

| Vaccum Sizing Tank | |||||

| Pump Drive ( KW) | 2.25 | 2.25 | 2.25 | - | - |

| Length ( Mtrs) | 3.0 | 1.0 | 1.0 | - | - |

| Water Requirement Circulating ( Ltrs/min) | 400 | 400 | 400 | - | - |

| Spray Bath | |||||

| Lengh (mtrs) | 3 | 5 | 5 | 6 | 6 |

| Water Requirement Circulating( Ltrs/Min) | - | - | - | 450 | 500 |

| Drive Range (kw) | 1.5 | 4 | 4 | 4 | 5.5 |

| Haul Off | |||||

| No. of Arms | 2 | 2 | 2 | 2 | 3 |

| Width of Belt (inch) | 4 | 6 | 6 | 6 | 2.5 |

| Cutting Saw | |||||

| Saw Diameter ( mm) | 300 | 500 | 500 | 500 | 200 |

| Saw Drive Load ( KW) | 0.75 | 1.5 | 1.5 | 1.5 | 2.25 |