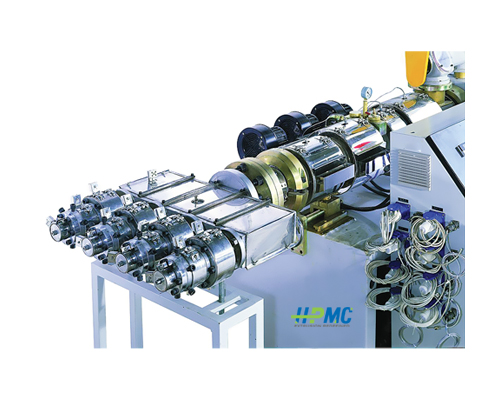

HPMC- PVC PIPE EXTRUDER - PVC CONDUIT PIPE PLANT (FOUR PIPES)

PVC Conduit Pipe Plant for pipes also recognized as Conical Twin Screw Extruder (Four Pipes) is type of extrusion machinery which is developed from high grade steel and is very useful in allowing lower consumption of energy while producing four pipes of variable weights and diameters at the same time from the single mould. With high production capacity of (250 kg/hr-350kg/hr) even for smaller pipes HPMC-PVC Conduit Pipe Plant (Four Pipes) comes in as model numbers HPMC 65/132, HPMC 80/156.

Product Description:

Conical Twin Screw Extruder (Four Pipes) or PVC Conduit Pipe Plant (Four Pipes) available in HPMC 65/132 and HPMC 80/156 models is extensively employed in making electrical piping system and underground duct. It is technology enabled for producing a large number of small and big pipes within a very short period of time.

Salient Features of PVC Conduit Pipe Plant (Four Pipes)

- Conical Twin Screw Extruder for Four Conduit pipe is designed and is ideally suited for electrical piping systems and underground duct.

- It can produce four pipes of different weights and diameters in a single mould.

- Providing extrusion efficiency of (250kg/hr-350Kg/hr) it produces even larger number of pipes even for smaller sizes.

- This special conical twin screw extruder can take high filler loading in comparison to parallel twin screw extruder.

- Counter rotating conical twin screw machines on CNC “WWW” make thread milling machines by simulation software for better performance.

- Bi-metallic screw & barrel as a part of Conical Twin Screw Extruder provides two-three times more lifespan in comparison to nitrided screw & barrel.

Sections of Conical Twin Screw Extruder (Four Pipes)

1. Four Pipe Die Head

- Die head for smaller sizes of pipe ranges from 16mm-32mm along with stainless steel spider

- It provides surety of production of four pipes from a single mould keeping the cost of production to be low.

- It is provided with flow channel design and special treatment on the surface.

- Special flow channel provides the equal distribution of PVC in both moulds

- Even temperature and pressure remain even

- Die head for smaller sizes of pipe ranges from 16mm-32mm along with stainless steel spider

- Four Pipe Vacuum Tank ensures continuity of the production of one pipe, incase production of other pipe is stopped minimizing the wastage. It is formed of stainless steel.

- All vacuum parts are free from each other.

- Its manufacturing ensures the traction of two different speeds thus enabling the production of pipes of varying diameters.

- Drive to all four belts is provided through four independent geared motors.

- Space left between two tracks is adjusted by pneumatic cylinders.

- For the easy maintenance rubber pads are mounted on the chain.

- Enabled with chain drive and groove rubber pad to ensure that pipe would not slip away even at higher line speed.

- Its manufacturing ensures the cutting of two pipes at varying lengths and at different time.

- Length of the pipe can be fixed with limit switch of tipping chute

- PLC Controlled” Functioning

- Specialized high sped blade for smooth cutting

2. Four Pipe Die Head

3. Four Pipe Haul Off

4. Four Pipe Cutting Unit

We manufacture and export plastic processing machinery like Plastic Extruder, Twin Screw Extruder, PVC Pipe Plant, Pipe Extruder, HDPE Pipe Plant, Recycling machine, Plastic Reprocessing Plant, Co-Rotating Extruder, Drip Irrigation, Compounding Extruder, Pipe Machinery, PVC Casing Caping Machinery, Plastic Profile Machinery, LLDPE Pipe Plant and all kinds of Extrusion Machinery and Plastic Machinery.

| MACHINE MODELS | HPMC 65/132 | HPMC 80/156 |

| Min Pipe OD ( mm) | 16 | 16 |

| Max Pipe OD (mm) | 32 | 32 |

| Max Plasticizing Capacity (Kg/hr) | 250 | 350 |

| Max Output (Kg/hr) | 220 | 320 |

| Main Drive (Kw) | 37 | 55 |

| Heating | ||

| Barrel ( Kw) | 24 | 36 |

| Die ( Kw) | 12 | 12 |

| Screw Speed Variation (RPM) | 1 - 37 | 1 - 37 |

| Vaccum Sizing Tank And Water Tank | ||

| Pump Drive ( KW) | 3.7x1 | 3.7x1 |

| Pump Drive ( KW) | 3 | 3 |

| Length ( Mtrs) | 3 | 3 |

| Water Requirement Circulating ( Ltrs/min) | 300 | 300 |

| Haul Off | ||

| Drive Range (kw) | 2.2x4 | 2.2x4 |

| Pulling Speed (mtr/min)Range | 2 to 6 | 4 to 10 |

| Cutting Saw | ||

| Saw Diameter ( mm) | 200 | 200 |

| Saw Drive Load ( KW) | 0.75x4 | 0.75x4 |