Product Description

We manufacture and export plastic processing machinery like Plastic Extruder, Twin Screw Extruder, PVC Pipe Plant, Pipe Extruder, HDPE Pipe Plant, Recycling machine, Plastic Reprocessing Plant, Co-Rotating Extruder, Drip Irrigation, Compounding Extruder, Pipe Machinery, PVC Casing Caping Machinery, Plastic Profile Machinery, LLDPE Pipe Plant and all kinds of Extrusion Machinery and Plastic Machinery.

1. CPVC Conical Twin Screw Extruder

- Counter rotating conical twin screw machined on CNC "WMW" German make thread milling machines by simulation software for better performance.

- Conical Twin Screw Extruders are specially designed for high calcium loading.

- Compact and reliable gear box.

- Two piece barrel construction for economical replacement can be provided.

- Synchronized drives of the extruder, feeder and haul off enables ease of operation. It is designed for high output at low screw speed and less power consumption.

2. Die Head

- Die Head is made of high carbon content forged alloy steel for better life and performance.

3. Spray Bath

- Intensive cooling of the pipe with the help of numbers of spray nozzles.

- Axial adjustment of tank on slide rails with locking arrangement.

- Self cleaning type spray nozzles with wide opening for intensive cooling of the pipe.

- Aerclyic transparent cover for easy inspection.

4. Pneuamtic Haul Off

- Twin and Multi Track system

- Track can be adjusted for different sizez of pipes 20mm to 315 mm

- Haul-off is synchronized with extruder with the help of AC Frequency Variable Drive.

- Gap between two tracks and pressure is adjusted pneumatically.

- V-Groove rubber pads mounted on chain with proper tensioning to prevent ovality even for large diameter and thin wall pipe.

5. Planetary Cuttings Saw

- Planetary saw blade cutting for pipe dia upto 315 mm

- UPVC chamefering rotary cutting.

- Cutting is PLC controlled.

- Saw dust powder sucking device.

- Special hard alloy saw blade employed to cut heavy caliber thick wall pipes.

6. Automatic Cutting Unit Upto 200 MM

- Carborundum cutter for less wastage during cutting.

- Smooth and clean cut.

- All movement are equipped with pneumatic cylinders.

- Clamping force can be adjusted to accomodate different wall thickness.

- Limit switch is provided to sense particular length.

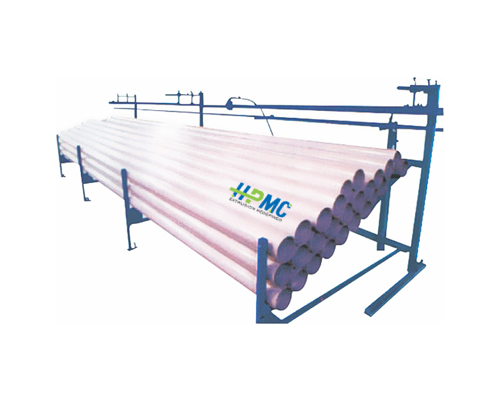

7. Tipping Chute

- Operated with pnematic cylinder and limit switch for pipe stacking.

Technical Specifications:

- MAIN SPECIFICATIONS

- CONICAL TWIN SCREW EXTRUDER

| MACHINE MODELS | MAX PLASTICIZING CAPACITY (KG/HR) | MAX OUTOUT (KG/HR) | MAIN DRIVE KW | HEATING BARREL (KW) | HEATING DIE(KW) | SCREW SPEED VARIATION (RPM) |

| HPMC 51/105 | 180 | 150 | 18.5 | 15 | 3 | 1-37 |

| HPMC 65/132 | 275 | 250 | 37 | 24 | 3 | 1-37 |

| HPMC 80/156 | 400 | 350 | 55 | 35 | 4 | 1-37 |