Application of Co-rotating Twin Screw Extruder

- Plastic and polymer application

- Direct compounding.

- PVC soft cable grade compounding

- lnline compounding

- Compression and injection molding

- Film and sheet extrusion

- In production of master batches, natural and wood fibre composites, plastic alloys,etc

- Recycling

Features of Co-rotating Twin-screw Extruder: Homogeneity, plasticization, filling modification, enhancement, recovery and granulation

- The newly designed torque distribution system,high-precision grinding of hardened gear teeth,and the interlocking of lubrication system are among the reasons for the good reliability of gear box

- Both screws and barrels are designed using the building block principle. The screw configuration, barrel setup, screw UD, the number and protocol of feeding and venting, screen change, way of granulating, and the electric control mode are optimally adjusted according to different material properties and process requirements,in consideration of the machine's versatility in other general applications

- Matched with single screw feeder or twin screw feeder; feeding smoothly and ensures easy operation

- It is provided with die face cutter and vibratory sieve

- Polymer with 80% Talc in single process

- Polymers with 50% Glass Fibre in single process,/b>

- Longer L/D ratio results in optimum power consumption and higher production

- Co-rotating twin screw extruder is best suitable for materials that need rigorous mixing like different master batches

- Can be fitted with up to 3 side feeders to add talc up to 80%, glass up to 50%, or other materials to achieve different material properties

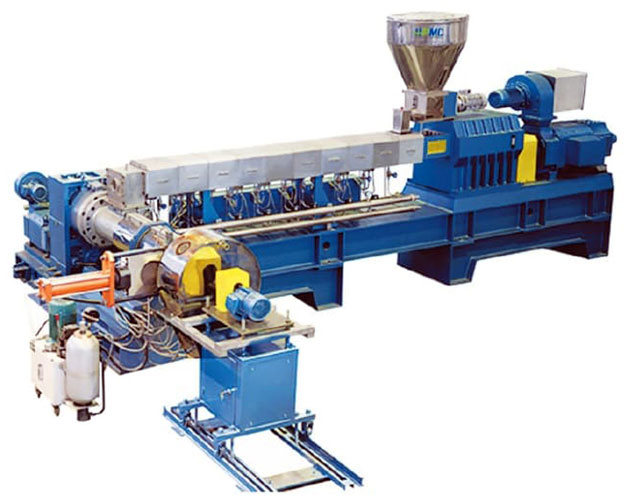

HPMC introduces Co-rotating Twin Screw Extruders for economical production of long fibre reinforced components.

Benefits

Technical Specifications

| MODEL | 20 | 30 | 35 | 50 | 65 | 72 | 92 |

| Screw Diameter(mm) | 21.7 | 30 | 35.6 | 50.5 | 62.4 | 71.2 | 91 |

| Rotary Speed (RPM) Max | 600 | 400 | 600 | 500/600 | 400/500 | 400/500 | 400/500 |

| Main Motor Power (kw) | 4 | 11 | 11/15 | 37/45 | 55/75 | 90/110 | 220/250 |

| L/D | 32-40 | 28-48 | 32-48 | 32-48 | 32-48 | 32-48 | 32-40 |

| Capacity (kg/h) | 2-10 | 5-30 | 10-80 | 20-150 | 100-300 | 300-600 | 600-1000 |